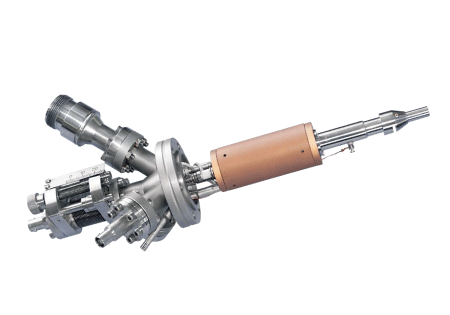

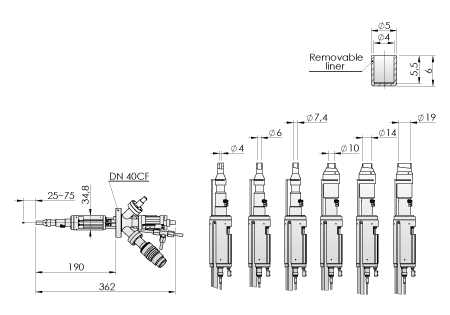

The electron beam evaporator EBV 40A1 is designed for ultra-pure sub-monolayer and multilayer thin film growth by molecular beam epitaxy. The precisely defined evaporant beam means highly uniform deposition on the sample, the deposition area being determined by the distance from the E-beam evaporator to the sample and the choice of one of the easily exchangeable exit apertures. The electron beam evaporator EBV 40A1 is configured with choice of manual or automatic shutter. Custom insertion length 190 – 345 mm (other on request).

Mounting flange DN 40 CF (rotatable)

Temperature range 160 °C – 2300 °C

(for evaporated (3300 °C for molybdenum connector)

materials)

Filament current typically 1.8 – 2.2 A, max 2.3 A

Evaporating rod 2 mm standard (other on request);

diameter step 2 mm, wire feed 25 mm,

wire length 43 mm

Water cooling water flow > 0.5 l/min

(required) temperature: 20 – 30 °C

max pressure: 6 bar

Exit aperture set 1: ID 4, ID 6, ID 7.4 (standard)

diameters set 2: ID 10, ID 14, ID 19

Type of shutter manual or pneumatic

Power ▪ 50 W for high vapor pressure materials

▪ up to 200 W for crucibles and thick wires

Energy range 1 – 1500 eV

Cathode type thoriated tungsten

Crucible type Knudsen cell type made of: Mo, W, liner

(option) PBN, Al2O3

Crucibles volume 0.07 ml

Evaporated all typical materials according to crucible

materials type

Others ▪ flux regulation via ion current incl.

electrode, feedthrough, display unit and regulator

▪ rear-loading evaporant

Insertion length min. 190 mm (other on request);

OD: 34.8 mm

Deposition area dependent on working distance (e.g. 6 mm for distance 25 mm – ID 4,33 mm for distance 75 mm – ID 19)

Working distance 25 – 75 mm (optimum)

Bakeout temp. up to 250 °C

Working pressure < 10-5 mbar